Join our team – We are looking for talented & driven people to come work with us. Join Now

We Are The Best Steel Forging Company

Taj Forging Pvt. Ltd is a provider of world-class forging solutions, from forging a single piece to large quantities, every part is manufactured on time. Established in 1983, Taj Forging provides you with more than four decades of expertise. The leading manufacturers in the country have used our premium forging solutions in the field of closed-die forged components.

■ OUR POLICY

“We are committed to achieve Total Customer Satisfaction by Delivering Quality Goods and Services on Time. Involvement of all Employees is ensured to continually improve the effectiveness of Quality Management System.”

■ OUR MISSION

“Achieve leadership through constant innovation and Continuous improvement in every sphere of our activity...”

■ OUR VISION

“We will strive to attain Leadership in all the Products and Services that we provide, through socially and environmentally acceptable means.”

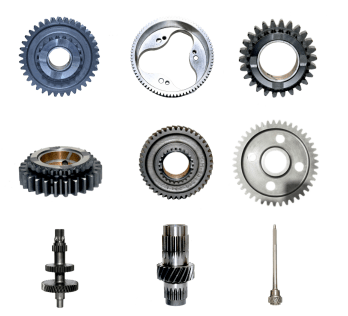

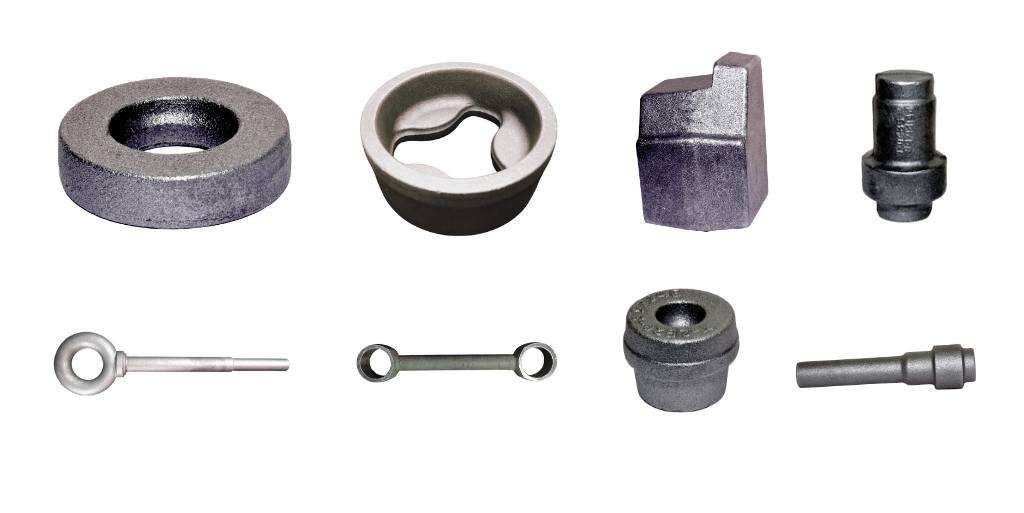

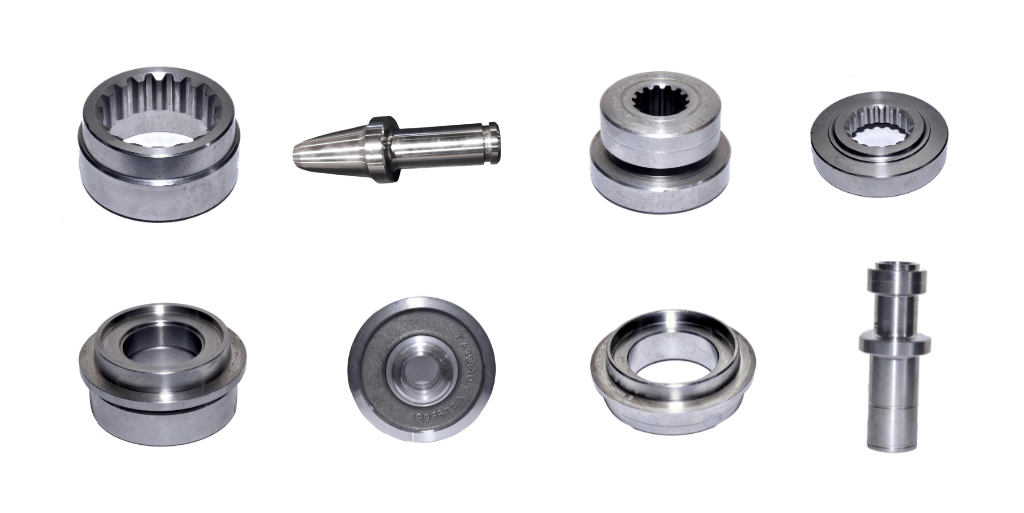

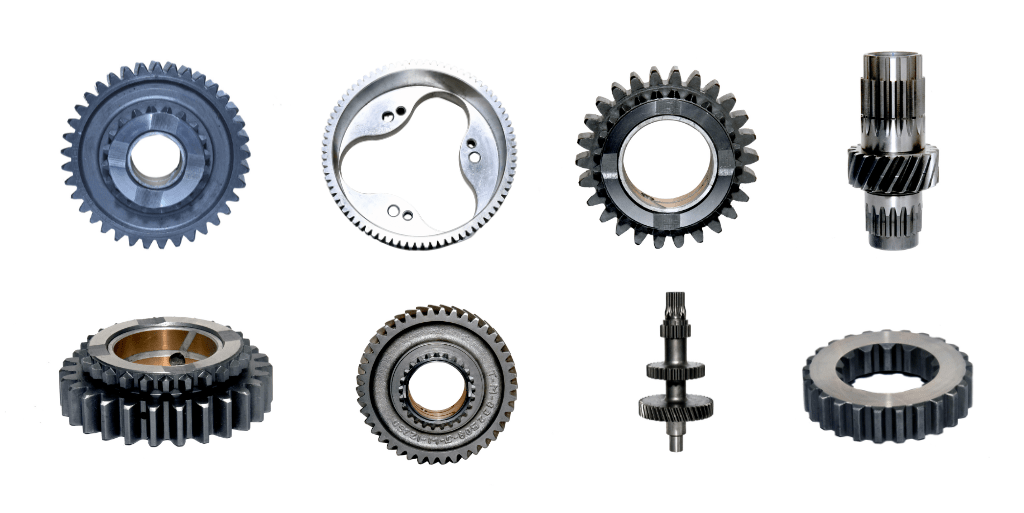

Our Product & Services

High-Quality Forged Components You Can Trust

We offer our customers a diverse variety of products and services. We are known as the best engine and transmission gears and shafts manufacturers in India because all our clients get excellence and reliability with our services. Usage of advanced technology and engineering-driven development processes have made us the pioneering steel forging company. We offer various components such as –

Established in

Machines

Why Choose Taj Forging Pvt. Ltd?

We have maintained the right business system that fosters innovation. With us, you get –

To offer high-strength forged components for automobile and other industries, we work on our fully integrated plant. From forging to machining and gear & shaft manufacturing, we have everything under one roof for a seamless production process.

To give our customers top-quality products, the plant needs to run 24/7. And this is possible with 100% power backup along with a dedicated 3 MW feeder line. Our plant can run hassle-free 24/7 due to these facilities. The secret of our timely delivery is the continuous production, thanks to the power supply day and night.

Our Infrastructure & Facilities

Our advanced infrastructure facility handles every step

The best part of our forging process is that every stage of gear manufacturing is done in our in-house setup. Our advanced infrastructure facility handles every step with attention to detail from steel-cutting to packaging. With the help of this streamlined process, our clients get top-quality services along with faster new product development and reduced lead times.

Forge Shop

In our forging shop, we have 5 belt drop forging hammers. These hammers range from 1 ton to 3.5 tons, which allows us to handle a wide variety of components. To meet high-volume demand, we have an installed capacity of 1000 MT per month. To meet the various industry needs, we mass-produce parts weighing from 0.5 kg to 40 kg.

Tool Room and Design

Our fully-equipped tool room has VMC, CNC, shapers, Grinders, etc. Our forging dies in-house facility allows us to offer our customers products with precision and accuracy. With the advanced setup, we can meet diverse forging requirements.

Machine Shop

Taj Forging Pvt. Ltd has a machine shop as well with CNC, VMC, Broaching, Drilling Machines, etc. With these machines, we do precision machining of forged components. The complete in-house production enables us to process efficiently. We can finish all the parts to meet the industry standards. With our machine shop, we promise durability and superior quality.

Gear Shop

We can provide top-quality products because of the advanced machinery. In our gear shop, we have CNC Hobbing, CNC Gear Shaving, CNC Gear Shaper, Rounding, Chamfering and many other hi-tech machinery. These machines help us to manufacture high-quality helical and spur gears. A total installed capacity of 1,50,000 gears and shafts per month allows us to have high-volume production.

Heat Treatment

Our premium forging solutions are heat treated in-house. Facilities like normalising, ISO Annealing, Annealing, Hardening & Tempering, Gas carburising, etc, are in-house to enhance the durability and strength of our products. We make sure that all our products meet the high standards of the industry. Keeping the whole process in-house lets us control the quality and have faster turnaround times.

Lab

To give our customers quality assurance, we have a fully-equipped lab. In our lab, we have machines including a Spectro Meter, Brinell Hardness Tester, Rockwell Hardness Tester, Micro Vickers Tester, Microscope with Image Analyzer, and Magna Flux Machine. With these advanced machines, we can conduct precise material and hardness testing.

Specific Measuring Instruments

We also have specialized measuring instruments to offer industrial forging solutions. These measurements include a CNC Gear Tester, CMM, XRF Gun, Bench Centers, Contour Tracer, Roughness Tester, CNC Gear Rolling Tester, and Millipore Testing Machine. With these cutting-edge tools, we can conduct detailed inspections and quality checks.

Industries We Specialize In

Powering Industries with Precision Forging

We offer custom steel forging services to our customers. Our high-quality products are designed to meet the diverse needs of different industries. We work with a commitment to provide durable, long-lasting, and high-quality products. We can proudly ensure that our forged components can cater to the most demanding applications. We offer expertise in –

Automobile

Agriculture

Railway

General Engineering

Defence

Gallery

A Glimpse into Our Work

All functions including supply chain, value chain, project scheduling, manufacturing, services and spares, technology, R&D, etc. are integrated to give a complete solutions package.

Get In Touch

Fill all information details to consult with us to get sevices from us